Lotus Fiber Lasers - uMeta

.png)

The uMeta is a compact fiber laser marking workstation for metal and plastic parts, perfect for logos, serial numbers, and coding. It features a 305 × 305 mm T-slot bed, fully automatic pneumatic door with 180° access, multiple lens options, and 450 mm Z-axis travel controlled by software. An optional rotary axis handles cylindrical objects. The uMeta is space- and energy-efficient and built with recyclable materials.

Bed Size: 305mm x 305mm

lotus umeta SERIES FEATURES

Interchangeable Lenses

Standard 110 mm lens with optional 70 mm or 180 mm for flexible marking speed and quality.

Pneumatic Access Panel

Hands-free, low-noise panel for minimal wear and easy operation.

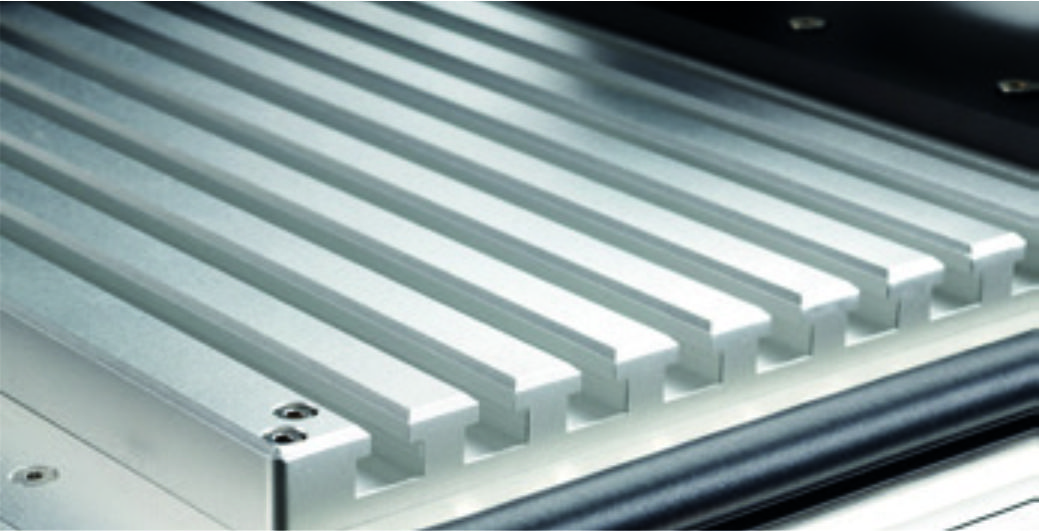

T-Slot Table and Pointing Laser

Solid aluminium table with pointing laser for quick, stable jig setup.

Programmable Z-Axis

Software-controlled Z-axis for fast multi-height marking in one job.

EUR (€)

EUR (€)