Epilog Fusion Edge - 12, 24 and 36

The Fusion Edge laser series takes our highest-quality engraving technology and incorporates it into smaller-format systems which allow customers to get the latest technology in a transportable format. The Fusion Edge machines feature a touch-screen display panel, on-screen artwork positioning with our IRIS™ camera system, and job trace functionality for quick and easy artwork setup

Fusion Edge 12: 24” x 12” (610 x 305 mm)

Fusion Edge 24: 24” x 24” (610 x 610 mm)

Fusion Edge 36: 36” x 24” (914 x 610 mm)

Fusion Edge Fiber 12: 24" x 12” (610 x 305 mm)

Fusion Edge Series, small format laser engravers are a great choice for both start ups and established engravers worldwide. A high-quality motion control system with metal/ceramic tubes from 30 watts to 80 watts. The Fusion Edge can be supplied with a CO2 or 30 Watt Fiber laser source.

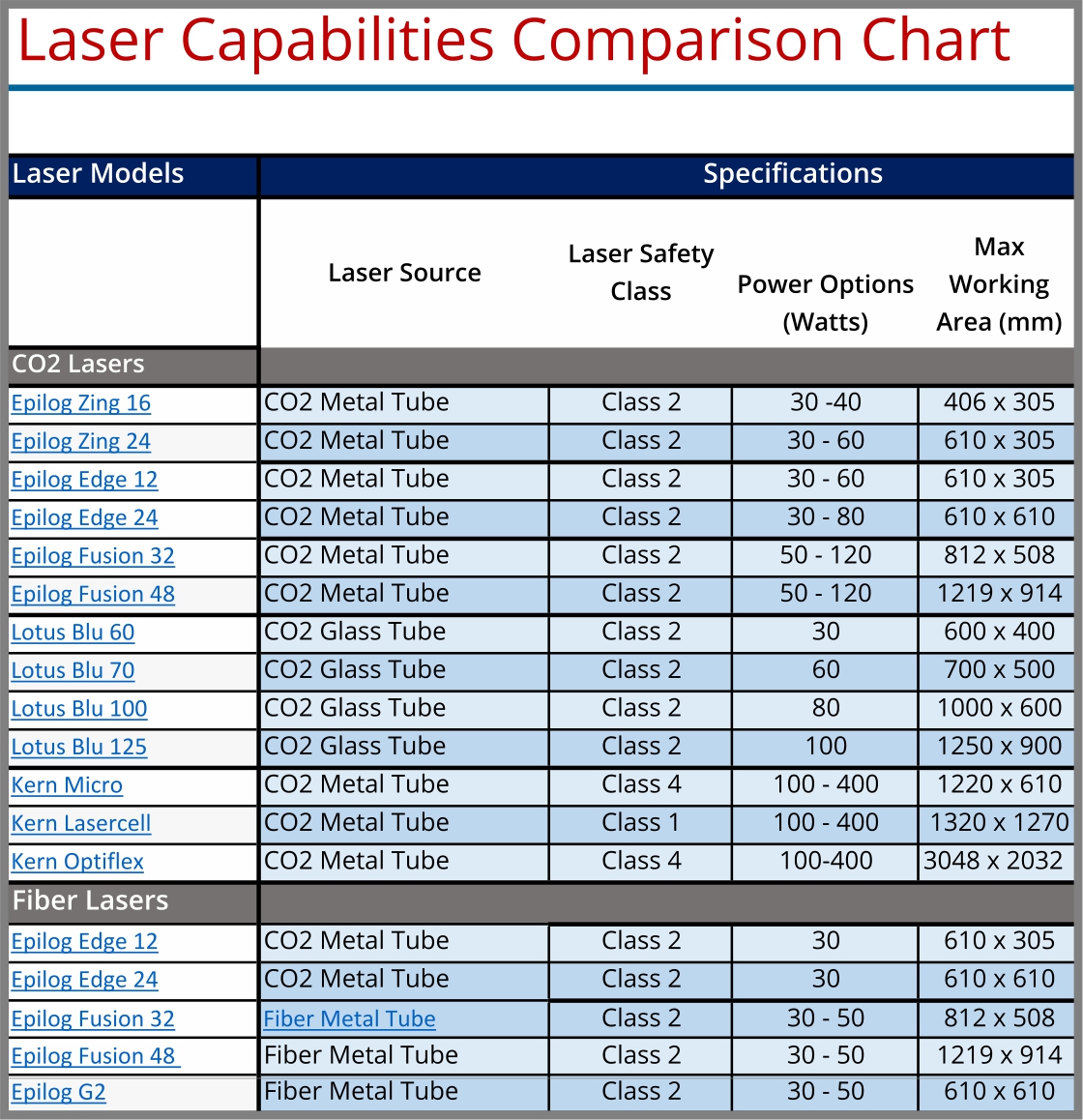

Specifications and Compatible Materials

Click the links below to find out more about the Epilog Fusion Edge specifications and a list of compatible materials.

Epilog Fusion Edge Specifications

Epilog Fusion Edge Specifications

Compatible Materials - CO2 Lasers

Compatible Materials - CO2 Lasers

Fusion edge SERIES TOUR

Check out the video below to get a full tour of the Fusion Edge Laser series and all it has to offer.

FUSION EDGE SERIES FEATURES

Check out some of the most impressive features of the Fusion Edge laser series below.

Highest Speed Engraving

The Fusion Edge’s 120 IPS (3.05 m/s) engraving speed and 5G acceleration provide the fastest engraving in the industry in a compact format.

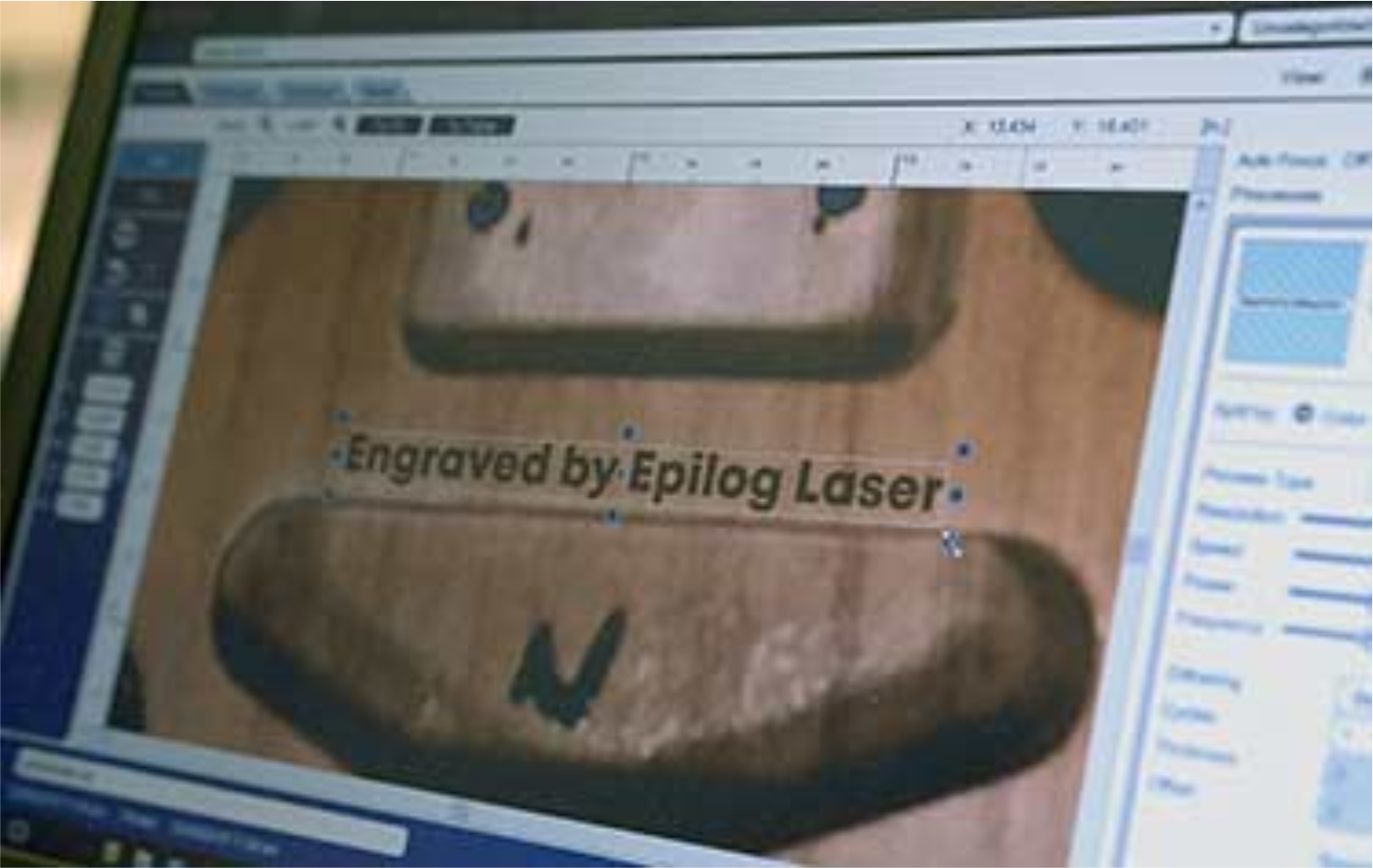

IRIS™ Camera Positioning

An overhead camera system provides a real-time picture of the working area for precise artwork placement. Drag and drop your artwork on screen for the fastest work processing

Touch screen at the laser

Select between jobs, auto focus the laser, and rerun jobs at the touch of a button from the easy-to-use touch screen interface right at the laser.

Network Across your Business

The Legend laser series features built-in Ethernet, USB and wireless connections

SAFEGUARD features

Keep the mechanics of your laser machine cleaner than ever before with side enclosures, a fully covered x-axis assembly, and a covered lens assembly

Air Assist

The air assist directs air right at the cutting surface to remove heat and combustible gases from the point of laser contact, providing a cleaner cut

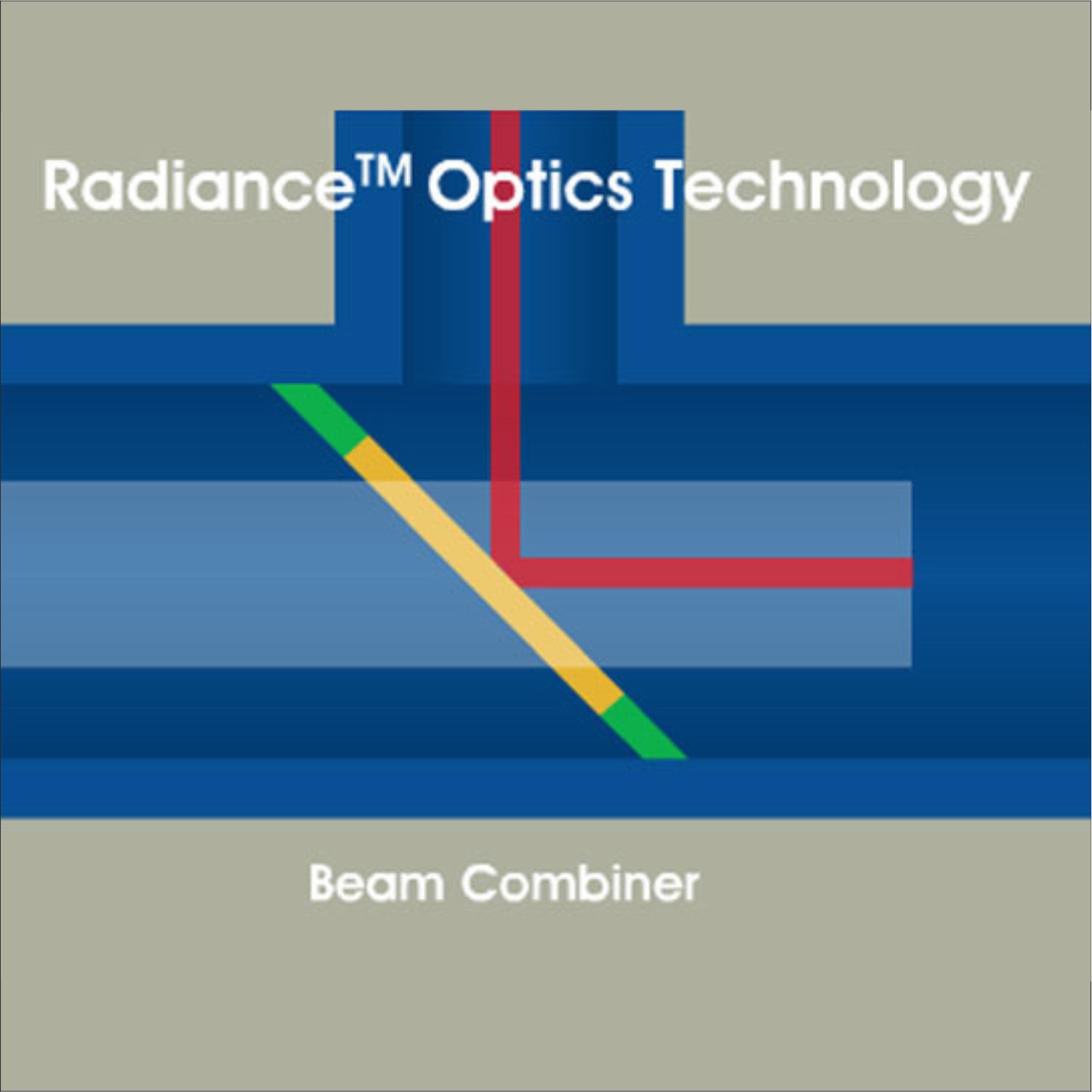

Radiance™ Beam Enhancing Optics

No additional, expensive lens package needed for the highest resolution engraving across the entire table.

1Gb Memory in The Machine

Improve job management and data integrity with 1GB of RAM. Save your most run jobs right at the laser..

CO2 Waveguide Laser Tube by Epilog

All metal tube design provides higher beam quality and longer life with low recharge costs

Long life Steel Bearing

A dual block design provides the most rigidity and reduced vibration eliminating the inevitable wobble and replacement of plastic bearings.

FUSION EDGE ACCESSORIES

Check out the accessories available for the Fusion Edge laser series below.

RIM Style Rotary Attachment

The Rim-Style rotary attachment adds the ability to engrave bottles, glasses, flashlights, or any other cylindrical item. The Fusion Edge rotary attachment is as easy to set up as placing your product on the rotary, raising or lowering the scissor lift to level the engraving area, and printing to the laser.

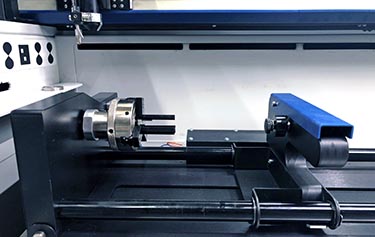

3 Jaw Chuck Rotary

With the 3-Jaw Chuck rotary, objects are clamped into the device's 3-jaw chuck, allowing you to rotate cylindrical or oddly-shaped items in applications that demand more precise alignment.

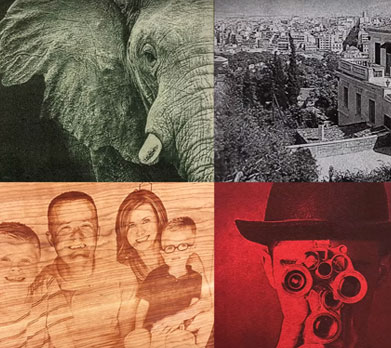

Photo laser Plus

PhotoLaser Plus takes photo engraving with your Epilog Fusion Edge laser to the next level by easily processing photos for engraving on all types of materials. Epilog Laser has partnered with CADLink to bring you the industry’s best photo processing software: PhotoLaser Plus. The easy-to-use software interface and powerful photo processing tools allow you to create the highest-quality photo engravings in the industry.

FUME EXTRACTION

Virtually all laser operation whether engraving, marking or cutting will give off different levels of smoke and fume depending on the material being converted. It is vital that these elements are removed in an efficient and safe manner to avoid poor quality cutting, potential corrosion of machine parts and danger to the operator. Discover more on fume extract here.

Virtually all laser operation whether engraving, marking or cutting will give off different levels of smoke and fume depending on the material being converted. It is vital that these elements are removed in an efficient and safe manner to avoid poor quality cutting, potential corrosion of machine parts and danger to the operator. Discover more on fume extract here.

EUR (€)

EUR (€)

Epilog full brochure

Epilog full brochure Compatible Materials - Fiber Lasers.

Compatible Materials - Fiber Lasers.